Metal parts and jewellery are frequently cast using ‘green sand’. Following some research I found various sources that suggested this could be achieved with kinetic sand. Kinetic sand is regular fine sand blended with a synthetic product, polydimethylsiloxane. This makes it behave like wet sand that can be moulded and shaped more readily than regular sand.

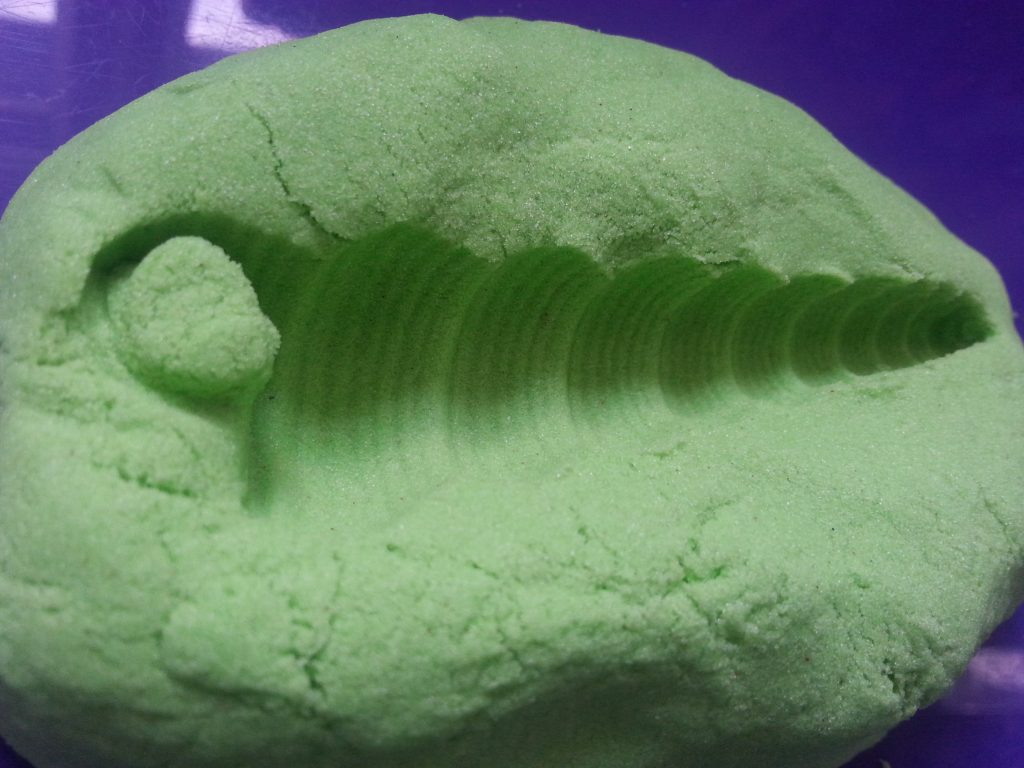

Before investing in a low temperature melting metal like pewter I thought it would be interesting to try a wax mould. I imprinted a block of kinetic sand (the green is a coincidence!) with a shell and melted wax into it with a heat gun. After leaving it to set, I attempted to remove the sand. Unfortunately, it did not fall off as I anticipated. Rather, it stuck resolutely to the wax and would not brush, chip or even wash off. I have a couple of thoughts. Possibly the wax did not get hot enough to set before the sand absorbed some of the wax. Possibly the sand also slightly melted and bonded with the wax.

On this basis I think I can safely write off the sand/wax combination! I may try other casting materials at some point but for now will move onto other experiments and moulding products.